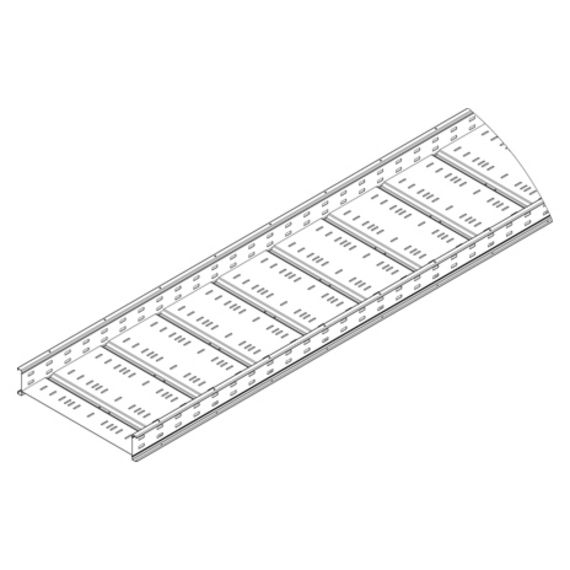

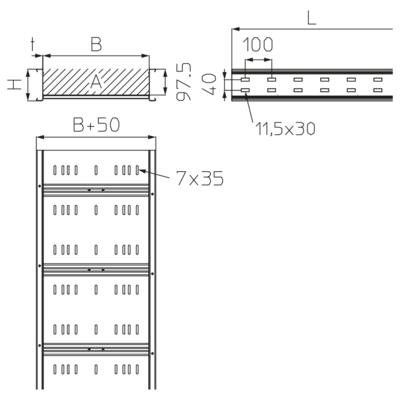

Wide-span cable tray, additional transverse rigidity due to welded and ripped inlay sheet. Electrical conductivity tested according to DIN EN 61537.

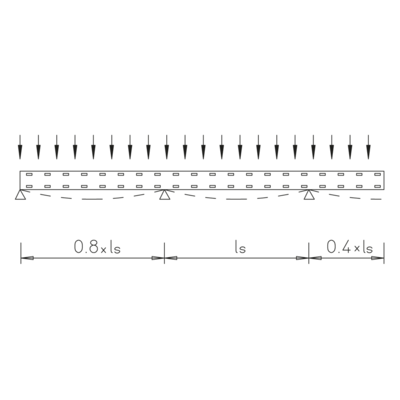

Assembly Instruction Continously hot galvanized (Sendzimir process) (DIN EN 10346)

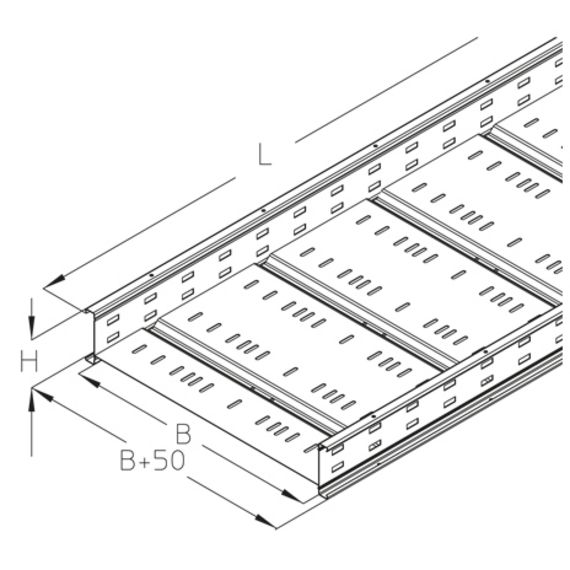

| height | width | length | t material thickness | A cross section area | QSKdistributed load control cable | weight | ||

|---|---|---|---|---|---|---|---|---|

| WPR 120-20S | 120 mm | 200 mm | 6000 mm | 1,50 mm | 196 cm² | 0,29 kN/m | 36,42 kg | |

| WPR 120-30S | 120 mm | 300 mm | 6000 mm | 1,50 mm | 294 cm² | 0,44 kN/m | 42,10 kg | |

| WPR 120-40S | 120 mm | 400 mm | 6000 mm | 1,50 mm | 392 cm² | 0,59 kN/m | 47,96 kg | |

| WPR 120-50S | 120 mm | 500 mm | 6000 mm | 1,50 mm | 490 cm² | 0,74 kN/m | 53,84 kg | |

| WPR 120-60S | 120 mm | 600 mm | 6000 mm | 1,50 mm | 588 cm² | 0,88 kN/m | 59,7 kg |

Hot-dip galvanized, according to BS 729 (DIN EN ISO 1461)

| height | width | length | t material thickness | A cross section area | QSKdistributed load control cable | weight | ||

|---|---|---|---|---|---|---|---|---|

| WPR 120-20F | 120 mm | 200 mm | 6000 mm | 1,50 mm | 196 cm² | 0,29 kN/m | 38,97 kg | |

| WPR 120-30F | 120 mm | 300 mm | 6000 mm | 1,50 mm | 294 cm² | 0,44 kN/m | 45,05 kg | |

| WPR 120-40F | 120 mm | 400 mm | 6000 mm | 1,50 mm | 392 cm² | 0,59 kN/m | 51,32 kg | |

| WPR 120-50F | 120 mm | 500 mm | 6000 mm | 1,50 mm | 490 cm² | 0,74 kN/m | 57,61 kg | |

| WPR 120-60F | 120 mm | 600 mm | 6000 mm | 1,50 mm | 588 cm² | 0,88 kN/m | 63,88 kg |

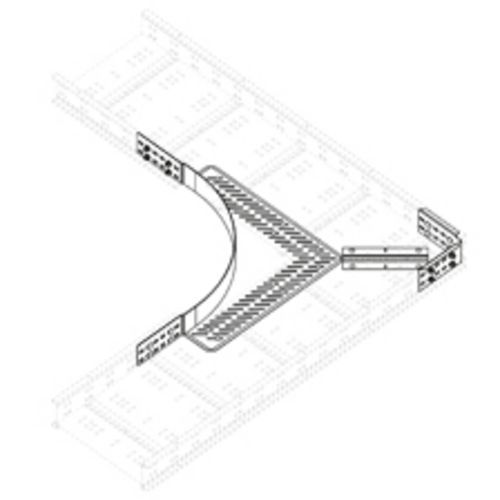

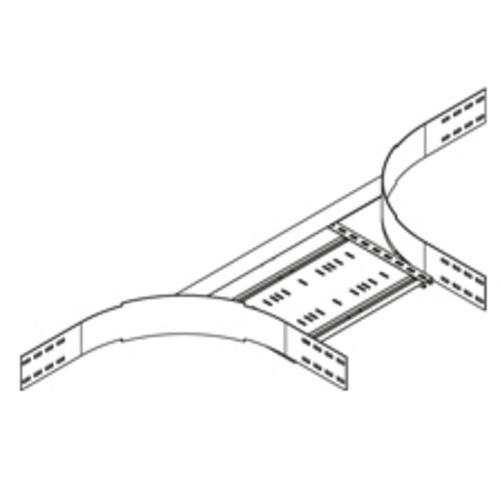

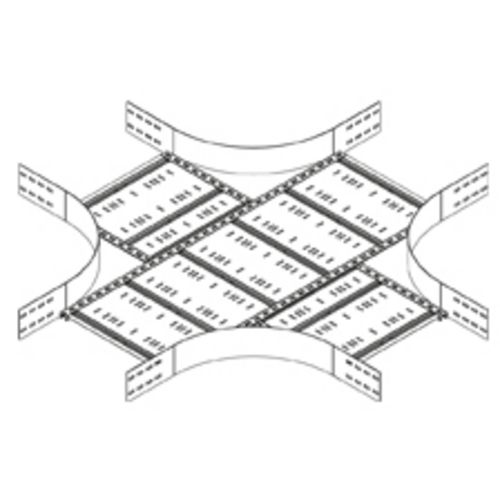

Cable trays

Cable trays  Cable trays certificate of compliance - UL

Cable trays certificate of compliance - UL