Initially, problems may go undetected, but the lack of proper clamps for our systems can lead to serious complications over the years. Therefore, in this post, we will explore the importance of cable ties, their role in cable management systems and how to choose the right ones to ensure the safety and efficiency of your installations.

What are cable clamps for festoon systems?

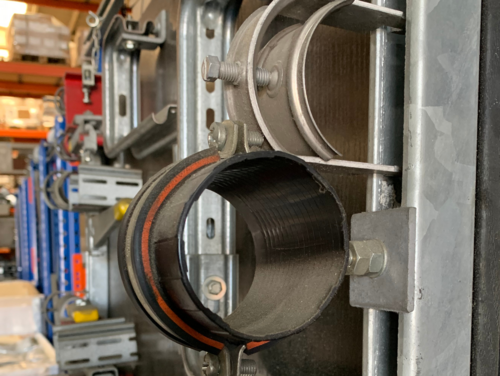

Cable clamps are used to support and secure cables within cable trays or trunking, holding them in place and preventing movement or slippage. They are designed to support various types of cables and adapt to different environmental conditions, providing a secure and stable hold. At PUK Portacables, in addition to being specialists in the manufacture of cable trays, we also excel in the manufacture and distribution of their essential components. In our product range, we have various solutions designed to support different types of cables. Our options include galvanised cable hooks, clamps for fixing to rails, for angled, flat and round profiles, as well as clamps for wall fixing and cable supports. These are the main functionalities offered by these components:

- Clamping and stability: The clamps ensure that the cables remain in place inside the cable trays. This prevents slippage and tangling or damage to the cables, which could result in electrical faults or even short circuits.

- Vibration reduction: In high vibration environments, such as tunnels or factories, the clamps act as shock absorbers, reducing the impact of vibrations on the cables. This helps prolong their service life and ensures consistent performance.

- Damage prevention: By keeping cables organised and secured, the clamps prevent contact with sharp edges or rough surfaces that could damage cable insulation. This is crucial to avoid safety issues and ensure the longevity of the electrical system.

- Ease of maintenance: A well-organised and securely clamped wiring system facilitates access and inspection during maintenance. This allows technicians to identify and resolve problems more efficiently.

How to choose the right clamp for your system?

As discussed above, poorly selected clamps can compromise the safety and performance of the system, so it is essential to consider certain key issues before making a decision.

The material of the clamp is one of the most important factors in its selection. Clamps must be made of materials that can withstand the environmental and mechanical conditions to which they will be exposed. In wet or corrosive environments, for example, it is essential to opt for clamps made of corrosion-resistant materials such as stainless steel or anodised aluminium.

The size and capacity of the clamp are equally crucial. The clamp you choose needs to be sized appropriately for the size and number of cables you wish to install. The clamps must be strong enough to support the weight of the cabling without deforming or allowing unwanted movement. In addition, they should fit the diameter of the cables without exerting too much pressure, to avoid damaging the insulation or the cable itself. Be sure to evaluate both the mechanical load and the diameter of the cables before selecting a clamp.

Finally, it is essential that the clamps comply with current safety regulations and certifications, which ensure that the products have been rigorously tested and meet the quality standards required for your project and are therefore suitable to withstand extreme conditions or specific environmental demands.

Our clamps are manufactured in accordance with DIN EN ISO 1461, which guarantees optimum corrosion protection through hot-dip galvanised coating, making them ideal for environments with high humidity or exposure to corrosive substances. In addition, we also comply with DIN 4102-12, which regulates the behaviour of materials in fire, ensuring that our clamps provide high heat resistance in critical situations, thus protecting electrical systems and reducing risks in the event of fire.

By choosing the right clamps, you can ensure reliable performance and increased durability in your installations. For more information about our clamp solutions and other products for cable management systems, please do not hesitate to contact us.