Perforated or Unperforated Cable Trays: When to Use Them?

When designing an industrial electrical installation, choosing between a perforated or unperforated cable tray is not a trivial decision. Both options offer technical advantages and limitations that can impact on the safety, efficiency, and maintenance of the system. This article explains when to use each type based on the installation environment, cable thermal requirements, and applicable standards.

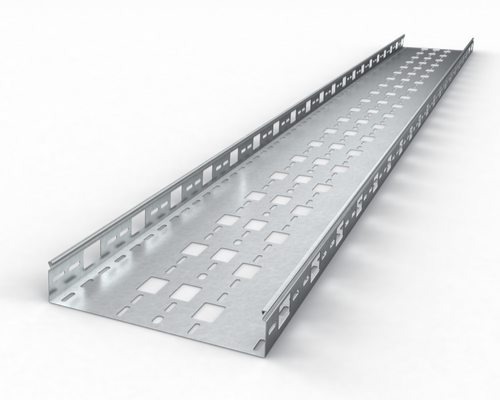

What is a Perforated Cable Tray?

Perforated cable trays have evenly spaced openings along the base. These perforations allow better airflow, which is crucial for high-power installations or environments where heat buildup could affect cable performance.

Key advantages:

- Better heat dissipation.

- Lighter structural weight.

- Easier visual inspection of wiring.

- Improved energy efficiency.

Common applications:

- Technical installations in industrial buildings.

- Data centers.

- High-voltage cabling projects.

Explore the full range of PUK’s perforated and unperforated trays available based on your project’s technical requirements.

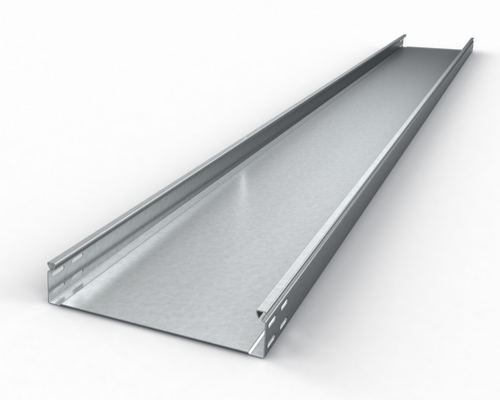

What is a Unperforated (Closed) Cable Tray?

Unlike perforated trays, unperforated cable trays are completely flat and do not allow airflow or particle escape. These trays are designed to protect wiring from harsh external conditions or where sparks, dust, or liquid contact must be avoided..

Key advantages:

- Isolation from external contaminants.

- Better fire protection (especially with lid).

- Conceals cables for better aesthetics in visible areas.

Common applications:

- Food or chemical industries.

- Exposed installations in technical buildings.

- Environments with explosions or splash risks.

Tray material also plays a crucial role. In this context, galvanized or stainless steel is highly recommended for its resistance and corrosion behavior in industrial settings.

Technical Comparison: Perforated vs Unperforated Tray

Feature | Perforated Tray | Unperforated Tray |

Cable ventilation | High | Low |

Protection from external elements | Medium (better with cover) | High |

Structural weight | Lighter | Heavier |

Cable visibility | High | Low |

Maintenance access | Easier | Requires opening or disassembly |

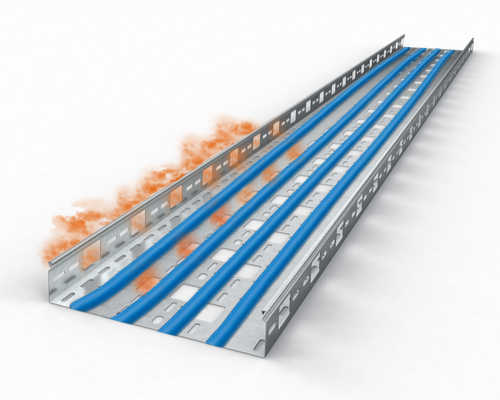

Ventilation and Energy Efficiency

One often underestimated aspect is how the type of tray affects the energy efficiency of an installation. Overheated cables perform worse, degrade faster, and require additional cooling systems. Perforated trays naturally dissipate heat, preventing thermal buildup and improving overall system performance. As our article on cable tray ventilation explains, this feature not only improves electrical performance but also extends cable lifespan.

→Reed more about energy efficiency and cabl trays

Standards and Technical Requirements

All cable tray systems must comply with DIN EN 61537, which sets requirements for:

- Mechanical load tests.

- Allowable deformation criteria.

- Equipotential bonding verification

→Also applicable is Spain’s ITC-BT Technical Guide which regulates safety, installation, and cable routing.

Types of Supports and Compatible Accessories

Both perforated and unperforated trays can be equipped with accessories that improve installation and adaptability:

Accesories:

- Horizontal and vertical bends

- T, cross, or L-branch connectors

- Protective lids (optional on perforated, common on unperforated)

- Cable dividers

- Wall or ceiling supports

These elements ensure a safe, modular, and flexible installation. Internal dividers allow energy, control, and data circuits to be organized without interference.

The choice of accessories also depends on the environment. For areas with fire risk or corrosive agents, sealed covers, stainless fixings, and anti-corrosion coatings are recommended.

Applications by Industrial Sector

Each industry has unique technical needs. Below are recommended setups by sector:

Food and pharmaceutical:

- Unperforated stainless-steel trays with mandatory lids.

- Mandatory covers to prevent residue buildup.

- Compatible with frequent cleaning.

Transport infrastructure (tunnels, metro, airports):

- Galvanized or stainless perforated trays with vibration/moisture resistance.

- Resistance to vibrations and moisture.

- Reinforced accessories for secure mounting.

Industry and energy (solar, chemical plants):

- Use both types; ventilation is key.

- Importance of ventilation for energy efficiency.

- Protection against corrosive agents or particles.

ICT/Data centers:

- Ventilated perforated trays with dividers for easy maintenance.

- Highly ventilated.

- Easy access for preventive maintenance.

FAQs

What is a perforated tray used for? For organizing and cooling cables safely and efficiently.

When is an unperforated tray necessary? In areas with liquids, industrial dust, sparks, or fire risk, or where visual concealment is needed.

Benefits over closed conduits? It is easier to install, lighter, better heat dissipation, and allows modifications.

Available sizes? Common tray widths range from 50mm to 600mm, depending on cable volume and layout.

What regulations apply? DIN EN 61537 governs structure and safety. In Spain, ITC-BT supplements this under the national Electrical Code.

Real Examples

Automotive industry: At SEAT’s Martorell factory, PUK supplies BK unperforated trays to protect wiring in high-spark or critical safety areas.

Rail infrastructure: In the Lesarri tunnel (Gipuzkoa), stainless steel perforated trays were installed for their ventilation and corrosion-resistant properties.

Which One Should I Choose?

Installation Type | Recommendation |

Data centers / Tech rooms | Perforated with optional lid |

Food/Chemical industry | Unperforated, stainless steel |

False ceilings / visible corridors | Unperforated with cover |

Solar / industrial projects | Perforated, galvanized or stainless |

ATEX / dusty or wet zones | Unperforated (sealed with cover if needed) |

Cost and Ease of Installation

Another factor when choosing between perforated and unperforated trays is the total system cost. Perforated trays are lighter and easier to handle, reducing installation time and labor costs. Unperforated trays require more structural support due to their enclosed design and higher weight.

Perforated trays also offer easier maintenance through visual access, while unperforated trays provide better protection in hostile environments but require disassembly for maintenance.

Common Mistakes When Choosing Tray Systems

- Failing to consider ventilation: Using a unperforated tray in high-heat installations can cause overheating.

- Ignoring standards: Non-compliance with DIN EN 61537 or ITC-BT may invalidate legal certification.

- Underestimating the environment: Using galvanized steel in humid/corrosive zones instead of stainless.

- Choosing only by price: Selection should focus on durability, safety, and maintenance, not just initial cost.

Conclusion

Choosing between a perforated or unperforated cable tray should not be based on aesthetics or availability, but on technical, efficiency, maintenance, and safety criteria. By understanding your project’s specific needs, you can make a decision that optimizes cost and extends system lifespan.

If you need personalized assistance, PUK Portacables offers a specialized team in cable support and routing systems.